Quick Links:

Engineering controls are considered the first line of defense in the laboratory for the reduction or elimination of potential exposure to hazardous chemicals. Examples of engineering controls used in laboratories at KAUST include dilution ventilation, local exhaust ventilation, chemical fume hoods, glove boxes, safety shields, and proper storage facilities.

Chemical fume hoods are installed in laboratories to protect individuals from airborne substances (gases, vapors, mists, fumes) generated by laboratory experiments. However, simply conducting these experiments in the fume hood does not guarantee adequate protection. The fume hood must be used properly.

These guidelines will help you optimize the effectiveness of your fume hood.

Be aware that the use of heated perchloric acid requires a special perchloric acid fume hood with a wash down function. DO NOT use heated perchloric acid in a regular fume hood. If heated perchloric acid is used in a regular fume hood (without a wash down function), shock sensitive metallic perchlorate crystals can form inside the duct work, and could result in causing an explosion during maintenance work on the ventilation system. If you are considering working with heated perchloric acid, then please contact HSE at hse@KAUST.edu.sa for more information.

Fume hoods must be inspected and tested annually to ensure that they are working properly. During the inspection, the air flow face velocity is measured and compared against recommended standards, and a smoke test is conducted to ensure adequate capture and containment. The fume hood is also checked for potential air flow interferences including excessive storage in the fume hood, blockage of the exhaust slots, HVAC vents located near the face of the hood, and location of the fume hood in a heavy traffic area. Fume hood inspections are conducted in accordance with the following standards:

ANSI/ASHRAE 110-1995, “Method of Testing Performance of Laboratory Fume Hoods”

Many of the fume hoods at KAUST are equipped with monitors that display a digital readout of the velocity of air being drawn into the hood. The monitor will alarm when airflows are too low or too high. Do not use the fume hood unless it is operating properly.

If you suspect your fume hood is not functioning properly, alert others by placing a sign that reads “Do Not Use” and report it to the Help Desk at 959 immediately.

The laboratories at KAUST are provided with general ventilation adequate for comfort and sufficient to supply air for chemical fume hoods and other local ventilation devices. Because the general air supply is not adequate for manipulating hazardous materials on an open lab bench, volatile or toxic chemicals shall be handled in a chemical fume hood or other appropriate containment device.

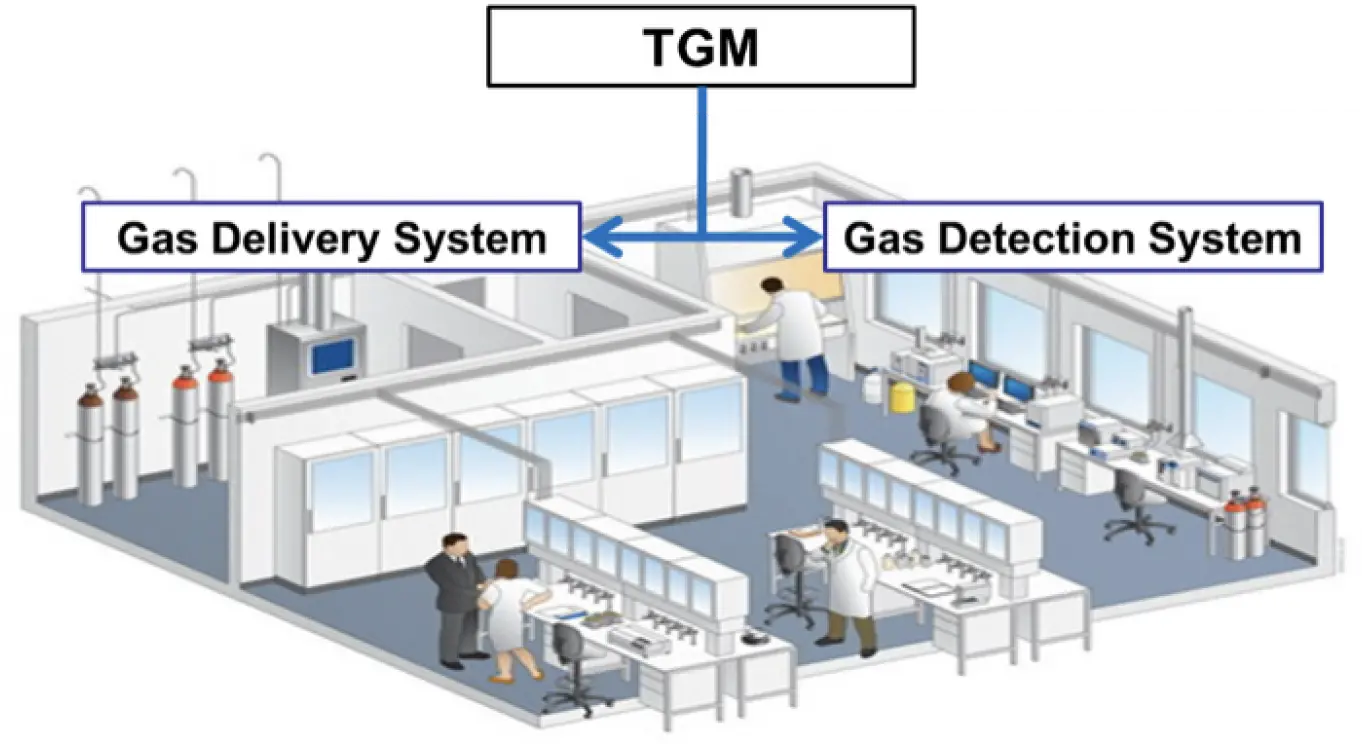

The TGM system is a sophisticated system that detects the presence of toxic and flammable gases and controls relevant actions such as the shutdown of gases from the gas delivery system, the shutdown of research tools, the activation of alarms and the activation of the emergency notification process. The need for gas monitors, as well as the number and locations of the sensors, shall be determined by the KAUST Research Safety Team in coordination with the KAUST Academic Projects Team based on hazard properties of the gas, possible worst-case release rates, size, and ventilation rate of the affected areas, as well as other risk factors. For system maintenance, sensor calibrations and facilities-related questions please contact: fmcallcenter@KAUST.edu.sa

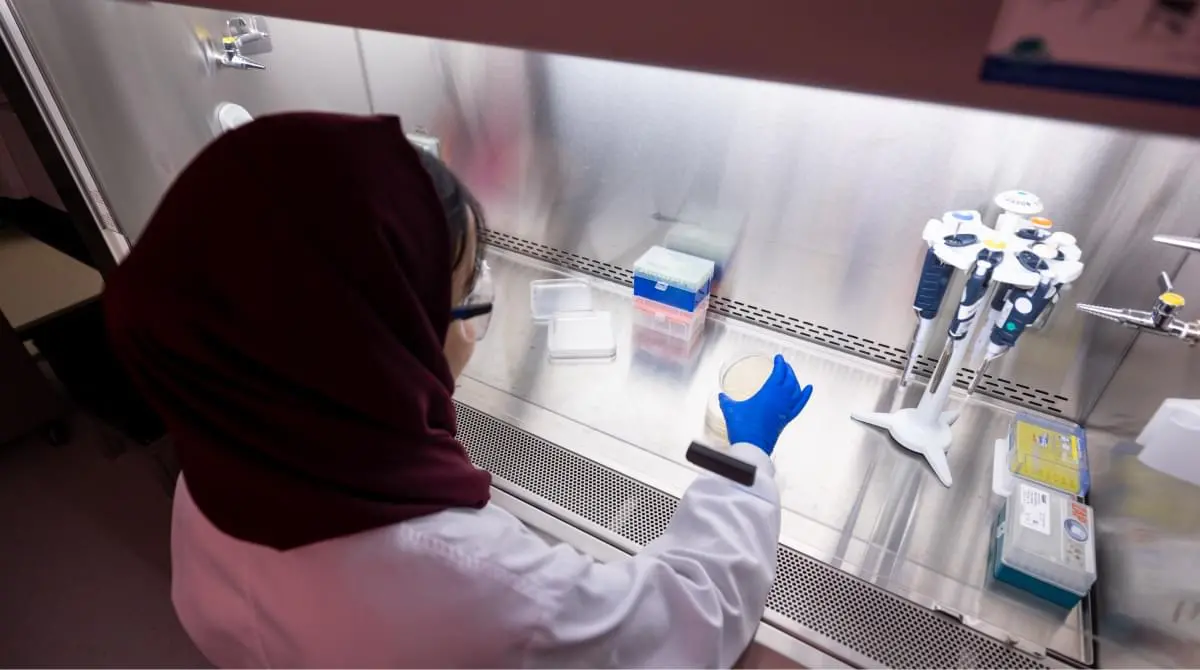

Biological safety cabinet (BSC) is an engineering device that reduce the risk of working with biohazardous and infectious microorganisms. BSCs of Class II and Class III are also used for maintaining aseptic conditions when working with cell cultures. BSCs utilize High Efficiency Particulate Air (HEPA) filters in the supply air and exhaust systems to create a nearly sterile work environment. Thus, BSCs provide personnel, environmental, and product protection when appropriate practices and procedures are followed.

There is a training that is recommended if you want to know more about biosafety cabinets. Biological Safety Cabinet Training

Laminar flow hood (LFH), also called clean bench, protects the product from airborne contamination, but does not protect the operator. Because of the risk to personnel, work with hazardous material in a laminar flow clean bench is not permitted. Use of clean benches should be limited to the preparation of sterile media, the assembly of sterile components into complete units (e.g., membrane filters), the examination of sterilized equipment and materials for possible contamination, and similar operations. BSCs and LFHs are certified on an annual basis. This is coordinated by HSE. Contact HSE if you have any of the following: New or moving a BSC or LFH. General questions about BSCs or LFHs. Issues you are having with your BSC or LFH.

Glove boxes are sealed enclosures designed to protect the user, the process, or both. They are usually equipped with at least one pair of gloves attached to the enclosure. The user manipulates the materials inside using the gloves. Typically, a glove box has an antechamber that is used to take materials in and out of the box. Gloves should be regularly inspected for cuts, tears, cracking and pinhole leaks. If defects are found, the gloves should be replaced. Note that there are many different types of glove box gloves that vary in thickness, material, size, etc. Choose the correct one for the glove box and application.

Regular maintenance and inspection is essential to ensure that a glove box is adequately protecting the user, the environment, and the experiment.

Routine maintenance procedures and the frequency of inspection (or certification) should follow the manufacturers and regulatory recommendations.

Ductless fume hoods and weigh stations utilize filter technology to remove chemical contaminants before discharging exhausted air back into the laboratory. Care must be taken to ensure that the unit has the appropriate filter for the intended application. Some units, intended for weighing powders only, afford no protection against chemical gases or vapors.

Contact HSE at hse@kaust.edu.sa if you have questions about the types of chemicals that can be used in ductless hoods and weigh stations.