Quick Links:

Before purchasing, installing or using a 3D printer, ask the following questions to determine the risks involved with a 3D printer.

What excess build material (resin, powder, biomaterial, etc) is being removed and what are its hazards?

Note: Since it is a build material, this hazard assessment should have been determined before even beginning.

How and where will you be cleaning the excess powder from your object?

Since many powders used for 3D printers are of very fine grade.

What are the hazards (irritants, flammable, GHS health hazard) of the excess build materials?

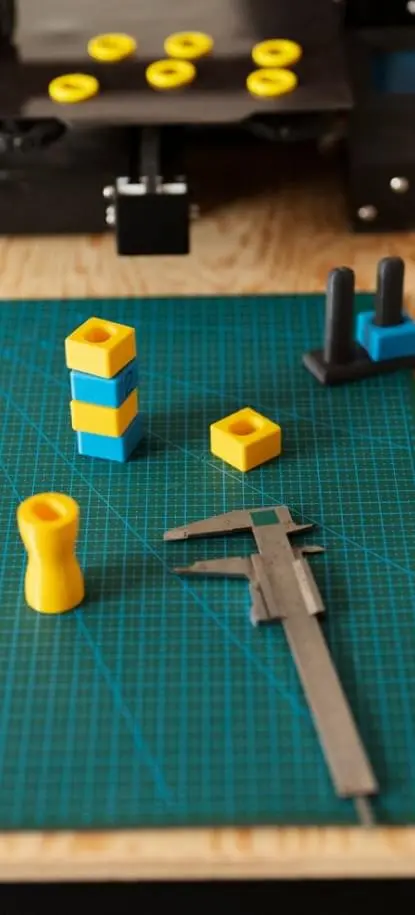

What tools are you using?

If a chemical bath, what are the hazards of the chemicals involved?

If a cutter, is it a mechanical or high energy cutter and does it introduce another hazard?

Where are the supports falling to?

The removed supports can be sharp, can they create a puncture hazard?

Surfaces smoothed or polished.

What tools and techniques will you be using?

How much dust will be created?

What are the hazards (flammable, toxic, corrosive) of the solvent?

What material (resin, particles, biomaterial, etc) is being removed? Curing (resin based build materials). Photopolymerized resins usually need to be cured further by placement in a heated oven and subjected to ultraviolet (UV) light to attain maximum strength.

Laser safety eyewear will be required if laser beam is directly accessible (i.e. servicing, maintenance, etc). Eyewear type will depend on wavelength and power level of laser. Contact hse@KAUST.edu.saif you have questions.

Respirator usage requires enrolling in the Respiratory Protection Program

Engineering controls should be used as much as possible when working with 3D printers. If you believe your current engineering controls are not sufficient and a respirator is needed, consult hse@kaust.edu.sa for further information regarding possible respirator usage.