Quick Links:

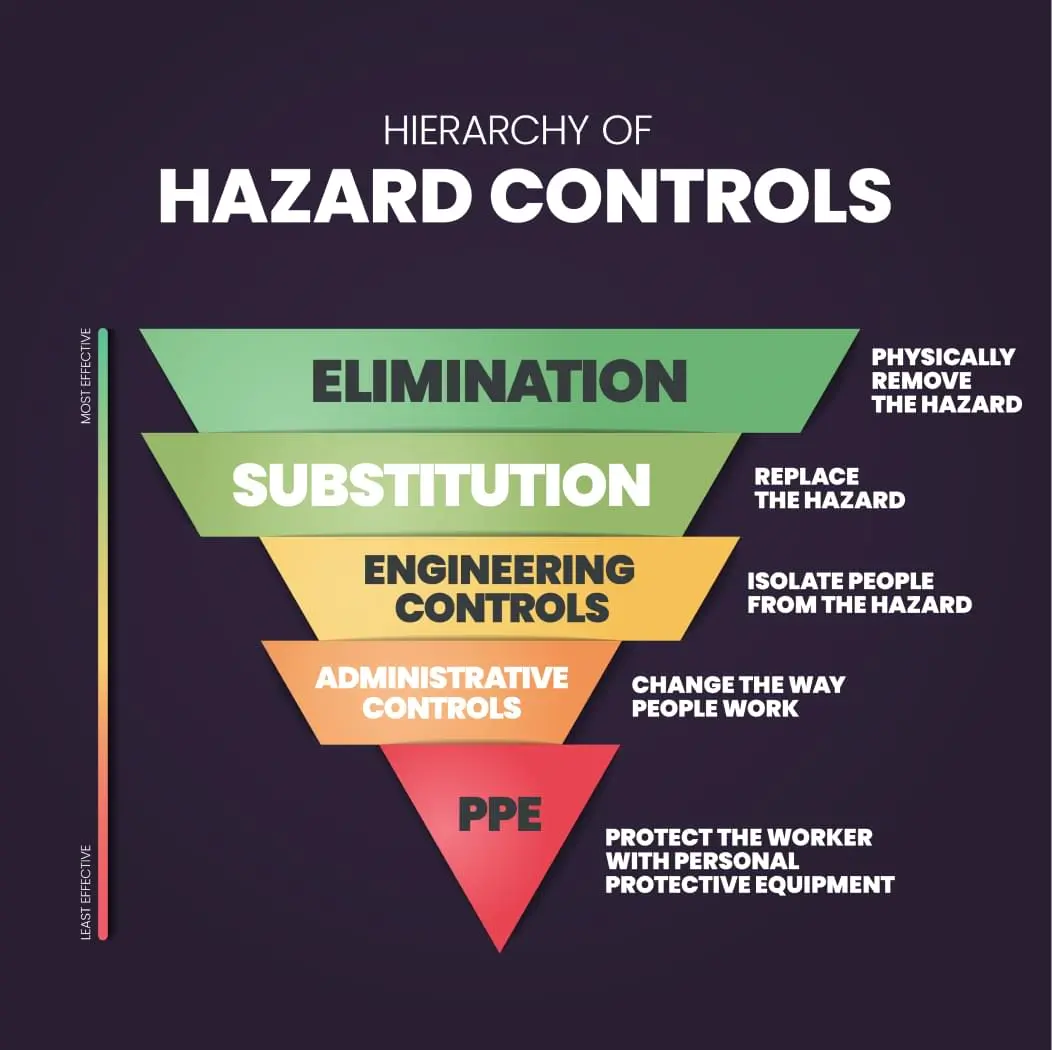

When evaluating the risks associated with specific hazards, the results of this evaluation should guide the researcher in the selection of risk management techniques including elimination, substitution, engineering controls, administrative controls, and personal protective equipment.

The hierarchy of controls is a method of identifying and ranking safeguards to protect workers from hazards. They are arranged from the most to least effective and include elimination, substitution, engineering controls, administrative controls and personal protective equipment

The most preferred method of controlling risk is to eliminate the hazard altogether. In most cases, elimination is not feasible and when possible, substitution is the best approach to hazard mitigation. When possible, substitute less hazardous agents in place of their more hazardo.

Counterparts. This also applies to conditions and activities. Examples include substituting benzene for toluene, lead-based paints for non-lead- based ones, etc.

Engineering controls consist of a variety of methods for minimizing hazards, including process control, enclosure and isolation, and ventilation.

Administrative controls are controls which alter the way work is performed. They may consists of policies, training, standard operating procedures/guidelines, personal hygiene practices, work scheduling, etc. These controls are meant to minimize the exposure to the hazard and should only be used when the exposure cannot be completely mitigated through elimination/substitution or engineering controls.

PPE should always be used as a last line of defense and is an acceptable control method when engineering or administrative controls cannot provide sufficient protection. PPE may also be used on a temporary basis while engineering controls are being developed. For more information, please refer to the PPE section on this site

The interstitial space procedures and guidelines is s to ensure a safe entry, exit, and emergency response during maintenance and operation inside Catwalk. The SOP applies to staff and contractors who enter interstitial space.

The first step to fall prevention is the elimination or minimization of the need for manual work at interstitial space.

The false ceiling and metal mesh are not adequate to hold any weight, therefore, minimizing the risk of working over interstitial space through:

This page describes storage and usage guidelines for the service corridor and its associated spaces. It also provides ordering information for metal cabinets and additional documents on these spaces. Please see the Service Corridor Procedures for more detailed information on service corridor requirements.